Please do not steal my artwork

Chapter

21a

Strakes & Fuel - your own strakes kit

Please do not steal my artwork

We usually try to build ahead whatever parts can be made to use up any slack or down time waiting for parts to set up or whatever else may be going on. If you cut out parts individually and glass them, then trim them this is going to be a very long process. What if instead you glue two sheets of foam together, glass both sides, trace all the parts on them, rough cut them with a band saw, trim to final size and sand a bit, done. It took a whole two days not including the skins.

We are going to outline how to make the parts for the plans version strakes as ours are different, but we started from here anyway. Also note that the layouts of parts per the plans will yield the most parts for the plane overall with the least amount of material, this layout is based on making all the parts for the strakes fast and efficiently without regard to other parts for the plane.

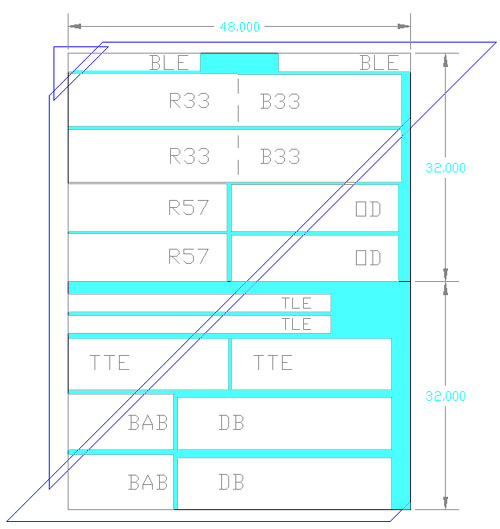

We edge glued 2 sheets of the 3/8" x 48" x 32" foam together using the tape hinge technique and 5 minute micro.

Next we micro'd the sheet and put on two layers of BID with the joints of the second layer perpendicular to the first.

Peel ply was applied to the whole side.

What we did next is just a short example of how we applied our LoVac technique:

On top of the peel ply we laid down two layers of paper towels to cover the entire layup

Next we put down two overlapping sheets of pallet wrap cling plastic to cover the whole side with about a 6" overlap of the two sheets and carefully patted the seam down so the cling wrap would self seal. There was about a 6" border of wrap around the edges.

We carefully turned the whole sheet over and repeated the procedure except we placed the LoVac tube next to one of the long edges then sealed the whole perimeter and turned on the pump.

To assure the part stayed flat we put down two sheets of 2' x 4' x 1/2" Masonite.

The layout of parts is such that you trace your templates onto the whole sheet, then rough cut the sheet up first horizontally with respect to the layout above, then rough cut it into individual parts, note that I have already joined R33 to B33 as indicated by the dotted line.

Lastly the fine cutting, trimming and sanding is done to template lines.

One last thing, make absolutely sure you put your templates on both sides and mark the 17.4" waterline and any joint locations, especially where the leading edges go.

Note: the LoVac technique yields light parts but they may have more pinholes, sealing has to be done very carefully.

There is a lot going on here so we decided to brake this down into four chapters:

Chapter

21a Your Own Strakes Kit -this is a huge time saver.

Chapter

21b Infinity Gear Installation

Chapter

21c Cozy Girrrl Strakes TM

Mod -what we did, how we did it.

Chapter

21d Fuel System -fuel for the fuel injected engine plus center

sump.